The need for a stable and reliable oxygen source on today’s industrial front is very important in health and manufacturing industries, water treatment, and the like. The need for an on-site, decentralized oxygen production that is fast and cost-efficient has created a market niche for PSA technology. Compared to old-fashioned cylinder supply, PSA oxygen generators are economical, environment-friendly, and, most importantly, reliable. In this blog, I’ll discuss details about PSA oxygen generators, how they operate, their advantages, and why the future of PSA oxygen production in industries is likely to belong to them. Whether you need information on the best oxygen system upgrade or PSA technology, this guide will help.

What are Oxygen Generators?

Oxygen generators refer to equipment meant to produce high-purity oxygen from the air in the environment. These generators are important in various industries that require frequent use of oxygen in huge quantities, including hospitals, the metal cutting and welding industry, and water treatment companies. Oxygen generators also help industries produce oxygen instead of using bulky, costly oxygen cylinders, which are a headache to transport. This reduces cylinder refills or deliveries needed, saving time and money in equal measure. It has been established that there are diverse kinds of oxygen generators; however, the PSA technology is among the most effective types, which we shall expound on in the following sections.

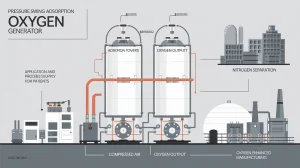

How PSA O2 Technology Works

Pressure swing adsorption (PSA) is the driving force behind all the advanced methods of oxygen production. PSA O2 generators differentiate oxygen from nitrogen in air, and the process delivers its oxygen continuously with high purity. Here’s a simplified breakdown of how it works:

Air Compression: In the generator, ambient air is drawn and compressed.

Adsorption: This separated air from the last step is then compressed and sent through molecular sieves that selectively adsorb nitrogen, and the non-adsorbed material is pure oxygen.

Pressure Swing: Through cycling pressure on two adsorption columns, nitrogen is adsorbed while oxygen is continuously produced.

The operation of this system is highly efficient and can generate high oxygen that is 95 per cent purity for industries. PSA oxygen generators are small, flexible in capacity, and even in size, making them suitable for small and large businesses.

Benefits of PSA Oxygen Generators

1. Cost Efficiency:

According to the evaluation of PSA oxygen generators, one of the major strengths is that they can save a lot of money. Here, companies can avoid enormous costs linked to transporting cylinders of oxygen as well as storage. Furthermore, the cost of operating PSA systems is lower than other oxygen supply modes, making them more affordable in the long run.

2. Reliable, Continuous Oxygen Supply:

This is cardinal since PSA oxygen generators grow oxygen continuously, so businesses always stay on time and are timely by oxygen deliveries. This is even more important for industries with a constant need for auxiliary products, such as oxygen supply, to be sustained and vital to processes that determine life and death in facilities, especially healthcare.

3. Scalable and Flexible:

This indicates that PSA systems can be designed to fit specific applications of various industries independently of the sizes of the scales, from small medical centres to large industrial ones. This versatility of PSA generators places the solution on a level ground regardless of the business size.

4. Eco-Friendly Solution:

PSA generators generate oxygen and do not rely on the constant transportation of oxygen cylinders; hence, they have less carbon emission. Third, on a broader level of technological innovation, the basics of the devices are relatively energy-friendly and thus are a form of green technology.

5. Low Maintenance and Long Lifespan:

PSA systems are made in such a way that they will have a long lifespan, and they are usually maintenance-free. The maintenance makes it possible to have such systems function properly for several years to provide confidence to the businesses that depend on them.

Case Studies

Case Study 1: PSA Oxygen Generators in Healthcare

A mid-sized hospital was based in Germany and was cutting a significant amount of cylinder-based oxygen. The hospital reduced its oxygen consumption by 40% when it shifted to a PSA oxygen generator supplied by Berg Gasetech while at the same time benefiting from the reliability of constant supply. This action made the organization run effectively and minimized the over-reliance on suppliers outside the organization.

Case Study 2: PSA O2 System for a Manufacturing Plant

In a case study of a German manufacturing plant that uses Iron and steel, one of the industry’s challenges is the random supply of oxygen for production. As a result of installing a PSA oxygen generator, the plant could secure oxygen much cheaper than in the past. By making this investment, it was also found that production flow was enhanced, and the overall operational costs were considerably cut down.

Testimonials

“Our healthcare facility installed a PSA oxygen generator from Berg Gasetech last year, and the impact was immediate. We no longer worry about running out of oxygen or managing cylinder deliveries. The cost savings and reliability have been outstanding.”

— Dr. Markus Weber, Medical Director

“The PSA system we purchased for our factory has been running smoothly since installation. It’s low-maintenance and has saved us thousands in operating costs. Highly recommended!”

FAQs (Frequently Asked Questions)

1. What is a PSA O2 generator?

A PSA O2 generator is an industrial process that utilizes Pressure Swing Adsorption to generate oxygen from the air without the need for bulky and expensive storage tanks.

2. How much does a PSA oxygen generator cost?

The cost of a PSA oxygen generator depends on the dimension and the working capacity needed in the application area.

3. How does PSA technology differ from other oxygen production methods?

PSA technology is more power efficient and suitable for small to middle-oxygen generation, while the cryogenic process, being more powerful, is suitable for large scalability.

4. Do PSA oxygen generators require regular maintenance?

Yes, as mentioned earlier, PSA systems have low maintenance, but some routine maintenance will maximize the performance and longevity of the generator.

5. Can PSA oxygen generators be customized for my specific needs?

Of course, special PSA oxygen generators can be designed to produce the amount of oxygen required in every industry. More information on custom solutions can be found by contacting us.

PSA O2 technology is the most innovative oxygen supply technology, and it is changing industry trends regarding reliability, cost environment, and environmental conservation. From hospitals to chemical industries, PSA oxygen-producing systems offer an uninterrupted, high-purity oxygen supply, leading to an uninterrupted and cost-effective process. Are you looking forward to getting your business a PSA oxygen generator? Visit our catalogue for oxygen generators, and feel free to contact us for the best oxygen generator solution.