PSA Oxygen Generator: Reliable On-Site Oxygen Production

Discover OXYBERG® PSA Oxygen Generators made in Germany. Reliable, cost-effective, and portable solutions for medical and industrial oxygen production with 90-95% purity.

Learn how our advanced technology ensures a constant supply of pure oxygen for various applications.

OXYGEN PLANT

Compressed Air Specification

- Temperature range: +5 to +40ºC

- Air compressor quality: ISO 8573.1, Class 1: dirt and oil, better than Class 4 water; PDP: +3ºCtd

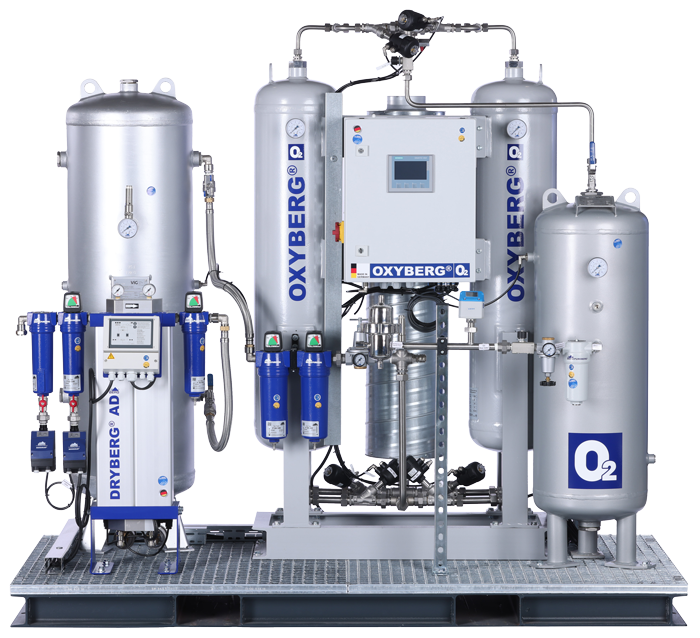

The Complete Oxygen Plant, Skid Mounted

- Compressed Air Station

- Air treatment to ISO 8573-1 Class 1.4.1

- Compressed Air Buffer Tank

- PSA Oxygen Generator, OXYBERG®

- Product Oxygen Tank

- Boosting Station / Cylinder Filling Station

Ambient Conditions

- Temperature range: +5ºC to +40ºC

- Operating pressure: 10 bar

- Electrical connection: 110-230 V/60-50 Hz

- Noise level: from 55 to max. 78 dB(A)

About OXYBERG® Made in Germany

During health emergencies, a reliable source of medical-grade oxygen is essential. One innovative solution that stands out is the Pressure Swing Adsorption (PSA) Oxygen Generator.

This cutting-edge technology ensures on-site O2 production, offering a dependable and sustainable supply for medical facilities, clinics, and industrial applications.

Oxygen Production Range:

- Oxygen from 0.5 Nm³/h to 261 Nm³/h

- Oxygen purity of 90% to 95%

How PSA Oxygen Generators Work

PSA (Pressure Swing Adsorption) Oxygen Generators operate on a fascinating and efficient principle to produce medical-grade oxygen. Here’s a simplified explanation of how they work:

- Compressed Air Intake: The process begins by pulling in the air we breathe, which contains mostly nitrogen (78%), oxygen (21%), and a small amount of other gases.

- Adsorption Process: At the heart of the oxygen generator are adsorption beds filled with a specialized material called zeolite. As the air passes through, the zeolite adsorbs the nitrogen, allowing the oxygen to pass through.

- Separation of Nitrogen: By actively changing the pressure in the adsorption bed, the zeolite releases the captured nitrogen. This step, known as desorption, produces a stream of high-purity oxygen.

- Oxygen Collection: The generated oxygen is collected and directed for use in medical or industrial applications. This on-demand production ensures a constant and reliable supply of oxygen without the need for storage.

- Cycle Repetition: The process is cyclical. While one adsorption bed is capturing nitrogen, the other is releasing it. This continuous cycle ensures a steady output of oxygen.

Key Features of BERG PSA Oxygen Generators, OXYBERG®

- On-Demand Oxygen Production Plant: The PSA Oxygen Generator works by removing nitrogen from the incoming air, leaving behind a stream of highly pure oxygen. This process happens as needed, eliminating the requirement to store large amounts of oxygen cylinders. This ensures a constant and reliable supply of oxygen without the hassle of storage.

- Cost-Effective Solution: Investing in a PSA Oxygen Generator can lead to significant cost savings in the long run. This system not only saves money but also makes the solution more economical and effective. The cost-effective nature of PSA Oxygen Generators provides a sustainable and reliable source of oxygen for various applications, reducing the need for stored oxygen and transportation costs.

- Reliability in Critical Moments: In emergencies, time is of the essence. The PSA Oxygen plant helps healthcare facilities quickly meet the increasing demand for oxygen in critical situations. This reliability is a game-changer in providing timely and adequate medical care, ensuring that patients receive enough oxygen and that oxygen therapy is effective when it matters most.

- Adaptable for Various Applications: Whether you’re in a hospital, clinic, or industrial facility, PSA Oxygen Generators actively cater to diverse requirements. The ability to adjust the system’s flow rate makes it suitable for a wide range of uses, including medical purposes, industrial oxygen production, welding, and other applications. This adaptability ensures that PSA Oxygen Generators are versatile and effective in various settings, providing purified oxygen efficiently.

- Environmentally Friendly: With a PSA Oxygen Generator, there’s a reduced carbon footprint compared to traditional oxygen supply methods. The energy-efficient design and the elimination of transportation contribute to a more sustainable and environmentally friendly solution. This eco-friendly approach aligns with the growing need for sustainable practices in oxygen generation and distribution, making it a preferred choice for both medical and industrial purposes.

Benefits of OXYBERG® PSA Oxygen Generators

- Plug and Play, Simple/Constant Oxygen Supply: Our PSA Oxygen Generators provide a simple, constant oxygen supply with a user-friendly plug-and-play design, suitable for medical and industrial applications.

- Constant Measurement of Oxygen Purity: Ensuring high-purity oxygen (90% to 95%), our generators constantly measure oxygen purity, ideal for oxygen therapy and other medical uses.

- Low-Maintenance, Compact Design: With a low-maintenance, compact design, these generators are easy to install and maintain, perfect for home oxygen concentrators and industrial settings.

- Longest Lifetime of High-Quality ZEOLITE: Featuring high-quality zeolite, our generators offer the longest lifetime and efficient nitrogen adsorption, enhancing reliability.

- Less Compressed Air and Low Energy Cost: Designed to use less compressed air, our PSA Oxygen Generators reduce energy costs, making oxygen production more cost-effective.

- Made in Germany: Made in Germany, our generators ensure high-quality engineering and durability, suitable for various applications, from medical treatments to industrial oxygen production.

Why Choose BERG GaseTech GmbH for PSA Oxygen Generators?

- Advanced Technology: BERG GaseTech leverages state-of-the-art technology in designing and manufacturing PSA oxygen generators. Proudly made in Germany, our products exemplify superior quality and innovation.

- Tailored Solutions: Our PSA Oxygen Generators can be customized to meet diverse needs. Whether you require specific flow rates or particular applications, our generators can be tailored to fit perfectly, catering to various industries and medical environments.

- Unmatched Reliability: Reliability is at the core of our operations. Our PSA oxygen generators are designed to ensure a steady and reliable supply of medical-grade oxygen, essential during emergencies or periods of high demand.

- Economical and Efficient: Opting for OXYBERG® means cutting down on oxygen capsule shipping costs and reducing dependency on external suppliers. Our solutions are not only cost-effective but also deliver high efficiency in continuous oxygen provision.

- Eco-Friendly Approach: At BERG GaseTech, we are committed to environmental sustainability. Our oxygen generators are energy-efficient, helping to lower the carbon footprint by eliminating the need for long-distance oxygen transportation.

- Proven Excellence: Our commitment to quality and innovation distinguishes us in the market. With a strong track record of delivering reliable and advanced oxygen generation solutions, we stand out as leaders in the field.

- Comprehensive Support: We offer more than just cutting-edge technology. Our team provides thorough support and service to ensure our PSA Oxygen Generators operate optimally. We are dedicated to assisting you throughout your journey with us.

Choose BERG GaseTech GmbH for PSA Oxygen Generators and benefit from a blend of advanced technology, consistent reliability, and a commitment to environmental sustainability.

Application fields:

- Medical: Ensure a constant supply of medical-grade oxygen for hospitals and clinics.

- Biogas Plants: Enhance biogas production efficiency with reliable oxygen supply.

- Ecology Fish Farming: Support sustainable fish farming with purified oxygen.

- Metal Industry: Improve processes in metal fabrication and welding with high-purity oxygen.

- Glass & Neon Factory: Optimize production processes with a steady oxygen supply.

- Processing: Ensure efficient oxygen use in various industrial processes.

- Water Treatment: Enhance water treatment processes with effective oxygenation.

- …and many more applications.

In the quest for a reliable and efficient oxygen supply, PSA Oxygen Generators emerge as a beacon of innovation

Their on-site production capability, cost-effectiveness, and environmental benefits make them an invaluable asset for any organization emphasizing safety, efficiency, and environmental responsibility.

Make a wise decision now – invest in a PSA Oxygen Generator. Ensure a continuous and reliable supply of medical-grade oxygen whenever and wherever you need it the most. Your commitment to excellence in healthcare begins with the reliability of on-site oxygen production.

BERG GaseTech GmbH – Empowering Lives Through Innovative Oxygen Solutions. (Made in Germany)

Contact Us Today

Ready to implement a reliable on-site nitrogen generation solution? Contact our sales team today to discuss your PSA Oxygen Generator needs. We look forward to providing a solution that enhances your efficiency.

Technical Data of PSA Oxygen Generator OXYBERG®

| Model | Oxygen Purity | 90% | 92% | 93% | 94% | 95% |

| OXYBERG® 500 | O2, Nm3/h Comp.air, Nm3/h | 2.9 31.9 | 2.5 27.5 | 2.1 23.1 | 1.9 20.9 | 1.8 19.8 |

| OXYBERG® 600 | O2, Nm3/h Comp.air, Nm3/h | 3.9 42.9 | 3.4 37.4 | 2.9 31.9 | 2.8 30.8 | 2.6 28.6 |

| OXYBERG® 700 | O2, Nm3/h Comp.air, Nm3/h | 4.9 53.9 | 4.5 49.5 | 4.2 46.2 | 3.9 42.9 | 3.8 41.8 |

| OXYBERG® 800 | O2, Nm3/h Comp.air, Nm3/h | 6.3 69.3 | 5.7 62.7 | 5.5 60.5 | 5.2 57.2 | 4.9 53.9 |

| OXYBERG® 900 | O2, Nm3/h Comp.air, Nm3/h | 8.1 89.1 | 7.3 80.3 | 6.7 73.7 | 6.4 70.4 | 6.2 68.2 |

| OXYBERG® 1000 | O2, Nm3/h Comp.air, Nm3/h | 10.6 116.6 | 9.4 103.4 | 9.1 100.1 | 8.5 93.5 | 8.1 89.1 |

| OXYBERG® 1100 | O2, Nm3/h Comp.air, Nm3/h | 13.6 149.6 | 13.3 146.3 | 12.7 139.7 | 11.8 129.8 | 11.4 125.4 |

| OXYBERG® 1200 | O2, Nm3/h Comp.air, Nm3/h | 15.7 146.7 | 13.8 146.6 | 14.2 146.5 | 13.6 143.0 | 12.9 141.9 |

| OXYBERG® 1300 | O2, Nm3/h Comp.air, Nm3/h | 23.4 357.5 | 22.2 244.2 | 21.1 232.1 | 20.1 221.1 | 19.3 212.3 |

| OXYBERG® 1400 | O2, Nm3/h Comp.air, Nm3/h | 32.5 357.5 | 31.9 350.9 | 30.2 332.2 | 28.9 317.9 | 27.6 303.6 |

| OXYBERG® 1500 | O2, Nm3/h Comp.air, Nm3/h | 44.6 490.6 | 42.8 470.8 | 41.1 452.1 | 39.9 438.9 | 38.8 426.8 |

| OXYBERG® 1600 | O2, Nm3/h Comp.air, Nm3/h | 53.4 587.4 | 51.4 587.4 | 49.3 542.3 | 47.4 521.4 | 46.2 508.2 |

| OXYBERG® 1700 | O2, Nm3/h Comp.air, Nm3/h | 64.7 711.7 | 63.4 697.4 | 61.6 677.6 | 60.3 663.3 | 58.8 646.8 |

| OXYBERG® 1800 | O2, Nm3/h Comp.air, Nm3/h | 89.1 980.1 | 85.2 937.2 | 82.2 904.2 | 79.7 876.7 | 77.1 848.1 |

| OXYBERG® 1900 | O2, Nm3/h Comp.air, Nm3/h | 105.4 1,159.4 | 101.7 1,118.7 | 97.8 1,075.8 | 93.8 1,031.8 | 91.4 1,005.4 |

| OXYBERG® 2000 | O2, Nm3/h Comp.air, Nm3/h | 129.6 1,425.6 | 126.9 1,395.9 | 123.4 1,357.4 | 120.7 1,327.7 | 117.4 1,291.4 |

*All values apply at 7 bar inlet pressure and 20ºC ambient temperature.

*Please contact us if you need a bigger size or customised plant.

Efficient Oxygen Solutions for Various Applications

At BERG GaseTech, we offer a range of oxygen generation solutions to meet diverse needs.

Our chemical oxygen generators provide a reliable source of oxygen in emergency situations and are designed to deliver 0.3 to 11 Nm³/h of oxygen. For more demanding requirements, our advanced chemical oxygen generator models can produce between 0.5 and 18 Nm³/h, ensuring a steady supply for critical operations.

For industrial settings, our industrial oxygen generator systems are engineered to produce 0.3 to 6 Nm³/h of high-purity oxygen. These generators are ideal for applications in manufacturing, metal processing, and other industrial processes that require a consistent and efficient oxygen supply.

Why Invest in a PSA Oxygen Generator?

- Reliable Oxygen Supply: Ensure a continuous and dependable supply of medical-grade oxygen.

- Cost-Effective: Reduce expenses associated with oxygen transportation and storage.

- Environmental Benefits: Lower carbon footprint with on-site oxygen generation.

- Versatile Applications: Suitable for medical, industrial, and environmental uses.

- Advanced Technology: Utilize cutting-edge Pressure Swing Adsorption technology for efficient oxygen generation.

Make a wise decision now – invest in a PSA Oxygen Generator. Guarantee a continuous and reliable supply of high-purity oxygen whenever and wherever you need it most.

Your commitment to excellence in healthcare and industry starts with the reliability of on-site oxygen production.

FAQ – Frequently Asked Questions

An oxygen generator is a device that produces high-purity oxygen from ambient air using advanced technologies like Pressure Swing Adsorption (PSA).

These generators are essential for providing a reliable and continuous supply of medical-grade oxygen for hospitals, clinics, and various industrial applications. By removing nitrogen from the incoming air, oxygen generators deliver purified oxygen efficiently and cost-effectively.

The primary difference between an oxygen concentrator and an oxygen generator lies in their applications and scale.

An oxygen concentrator is typically used for individual or home oxygen therapy, providing enough oxygen for patients with chronic obstructive pulmonary disease (COPD) and other respiratory conditions.

In contrast, an oxygen generator is designed for larger-scale operations, such as supplying oxygen to medical facilities, industrial processes, and water treatment plants.

Oxygen generators are more robust, capable of producing higher flow rates and purities compared to portable oxygen concentrators.

For medical-grade oxygen generators intended for personal use or home oxygen therapy, a prescription is usually required to ensure proper medical oversight.

However, industrial oxygen generators used in applications like metal processing, glass manufacturing, and biogas production do not typically require a prescription.

It’s essential to consult with healthcare providers or regulatory bodies to determine the specific requirements for your intended use.

PSA oxygen generators produce oxygen on-site, eliminating the need for medical oxygen suppliers or industrial oxygen cylinders.

This approach ensures a continuous oxygen supply without transportation costs, enhancing efficiency and saving costs. Additionally, PSA oxygen generators can be tailored to meet specific industrial requirements, offering flexibility and reliability.

Hyperbaric oxygen chambers provide therapeutic benefits by delivering oxygen at increased atmospheric pressure, promoting healing and reducing inflammation.

Medical facilities use them for treating wounds, infections, and neurological disorders. For home use, these chambers offer convenience and flexibility for long-term oxygen therapy, improving patient outcomes.

Oxygen compressors efficiently compress atmospheric air, facilitating oxygen extraction through methods like pressure swing adsorption (PSA).

This increases oxygen production rates and ensures a continuous supply. Oxygen compressors enhance the efficiency of both industrial oxygen generators and medical oxygen concentrators, making oxygen production cost-effective and reliable.