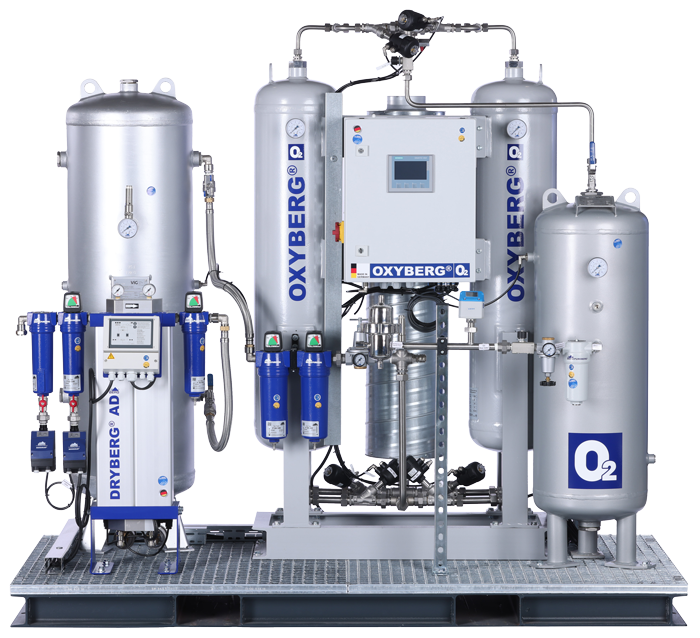

Oxygen Generators for Biogas Plants

Pressure Swing Adsorption (PSA) oxygen generators are commonly used in biogas plants to enhance the efficiency of anaerobic digestion and other processes.

This technology is both efficient and cost-effective, making it a preferred choice for industries requiring a reliable oxygen supply.

Key Features of our Oxygen Generators

PSA Technology

At the heart of our oxygen generators lies PSA (Pressure Swing Adsorption) technology. This technique uses a zeolite molecular sieve to selectively adsorb nitrogen and other gases from ambient air, allowing only oxygen to pass through. This process results in a stream of high-purity oxygen, ideal for enhancing biogas production.

High Purity Oxygen

Our generators deliver oxygen with purity levels meeting the stringent demands of biogas plants. This high-purity oxygen boosts microbial activity and optimizes biogas composition, ensuring increased methane production and improved energy value.

Cost-Effective Solutions

Generating oxygen onsite enables biogas plants to significantly cut down on external oxygen supply costs, leading to substantial savings. The efficiency of PSA technology ensures minimal operating costs, making it an economical choice.

Versatility and Applications

Our oxygen generators are versatile, catering specifically to biogas plant needs. From enhancing anaerobic digestion and odor control to improving wastewater treatment and biogas upgrading, these generators provide a reliable and tailored oxygen supply for various biogas plant processes.

Efficiency Increase of your Biogas Plant

- Cost Savings: Onsite oxygen generation eliminates the need for purchasing and transporting oxygen cylinders or liquid oxygen, resulting in significant cost savings.

- Reliability: Onsite oxygen generators ensure a continuous and uninterrupted supply of oxygen, critical for operations that cannot afford downtime.

- Customization: Our oxygen generators can be tailored to meet specific flow requirements and purity levels, providing a customized solution for each application.

- Environmental Benefits: By generating oxygen onsite, industries reduce their carbon footprint associated with the transportation and handling of oxygen supplies.

Understanding PSA Technology

Pressure Swing Adsorption (PSA) involves two vessels filled with zeolite molecular sieves. Compressed air passes through one vessel where nitrogen is adsorbed by the zeolite, allowing oxygen to pass through. The second vessel undergoes desorption, releasing the adsorbed nitrogen and preparing for the next cycle. This continuous process ensures a steady supply of oxygen.

Zeolite Molecular Sieve

The zeolite in PSA has a porous structure with a high affinity for nitrogen molecules, effectively separating nitrogen from oxygen to ensure high purity output.

Compressed Air

Ambient air, compressed and dried, is used as the oxygen source. This pre-treatment removes moisture and contaminants, enhancing separation efficiency.

Technical Specifications

- Oxygen Purity: Our generators are capable of producing oxygen with purity levels up to 95%, suitable for most industrial and medical applications.

- Flow Rates: The flow rates of our generators range from small units designed for specific applications to large systems capable of producing thousands of cubic meters of oxygen per hour.

- Pressure Levels: Our industrial oxygen generator can deliver oxygen at various pressure levels from 1-150bar, tailored to meet the needs of different industrial processes.

- Energy Efficiency: Designed with energy efficiency in mind, our generators utilize advanced control systems to optimize power consumption, ensuring cost-effective operation.

For more information on how our oxygen generator can benefit your operations, contact us today and let us help you achieve optimal oxygen generation for your biogas plant.

What our Gas Generators do for Biogas Plants

1. Anaerobic Digestion

Enhanced Microbial Activity: Anaerobic digestion is a biological process where microorganisms break down organic matter in the absence of oxygen, producing biogas. Introducing oxygen into the digestion process using PSA oxygen generators can enhance microbial activity, leading to more efficient degradation of organic materials and increased biogas production.

Optimized Biogas Composition: The controlled addition of oxygen with PSA generators allows for the adjustment of the biogas composition. This optimization can result in a higher methane content in the produced biogas, improving its energy value.

2. Odor Control

Biological Odor Treatment: Biogas plants often produce unpleasant odors due to the decomposition of organic materials. PSA oxygen generators can be used to supply oxygen to biological treatment systems that help control and mitigate odors generated during the anaerobic digestion process.

3. Wastewater Treatment

Aeration Tanks: In wastewater treatment processes associated with biogas plants, aeration tanks are used to provide oxygen to microorganisms that facilitate the breakdown of pollutants. PSA oxygen generators contribute to the aeration process, supporting the effective treatment of wastewater.

Nutrient Removal: The controlled addition of oxygen through PSA generators aids in nutrient removal processes, such as denitrification and phosphorus removal, improving the overall efficiency of wastewater treatment in biogas plants.

4. Landfill Gas Utilization

Methane Enhancement: Landfill gas is generated as a byproduct of organic waste decomposition in landfills. PSA oxygen generators can be employed to introduce oxygen into the landfill, enhancing methane production. This, in turn, can improve the feasibility and efficiency of landfill gas utilization projects.

5. Biogas Upgrading

Oxygen Removal: Biogas produced from anaerobic digestion often contains impurities, including oxygen. PSA oxygen generators can be used in the upgrading process to remove oxygen from biogas, resulting in a purified methane-rich gas suitable for injection into natural gas pipelines or use as a clean fuel.

6. Combined Heat and Power (CHP) Systems

Optimized Combustion: In CHP systems that utilize biogas for power generation, PSA oxygen generators can contribute to optimized combustion conditions. This ensures efficient energy conversion and maximizes the electricity and heat output from the biogas.

7. Biological Desulfurization

Sulfur Removal: Biogas produced from certain feedstocks may contain sulfur compounds that need to be removed for environmental and equipment protection reasons. Oxygen addition through PSA generators can enhance biological desulfurization processes, leading to reduced sulfur content in the biogas.