High-Efficiency PSA Oxygen System for Industrial Applications

Welcome to BERG GaseTech GmbH, your trusted provider of advanced OXYBERG® PSA oxygen systems. Our state-of-the-art oxygen generators are designed to meet the high demands of various industries, offering reliable and cost-effective oxygen production.

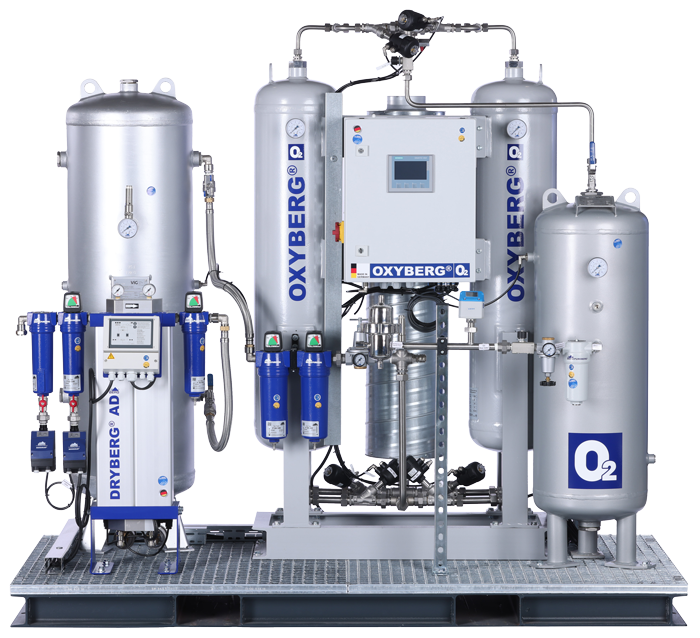

OXYGEN PLANT

Compressed Air Specification

- Temperature range: +5 to +40ºC

- Air compressor quality: ISO 8573.1, Class 1: dirt and oil, better than Class 4 water; PDP: +3ºCtd

The Complete Oxygen Plant, Skid Mounted

- Compressed Air Station

- Air treatment to ISO 8573-1 Class 1.4.1

- Compressed Air Buffer Tank

- PSA Oxygen Generator, OXYBERG®

- Product Oxygen Tank

- Boosting Station / Cylinder Filling Station

Ambient Conditions

- Temperature range: +5ºC to +40ºC

- Operating pressure: 10 bar

- Electrical connection: 110-230 V/60-50 Hz

- Noise level: from 55 to max. 78 dB(A)

What is our PSA Oxygen Generator?

Our OXYBERG® PSA oxygen systems stand out due to their advanced Pressure Swing Adsorption technology, which ensures efficient and reliable oxygen production.

A PSA (Pressure Swing Adsorption) oxygen generator is an advanced technology used to separate oxygen from air, providing a high-purity oxygen supply for various applications.

This system utilizes zeolite molecular sieves to adsorb nitrogen from compressed air, allowing oxygen to pass through and be collected. The PSA process involves two vessels filled with molecular sieves that alternate between adsorption and desorption phases.

As one vessel adsorbs nitrogen, the other regenerates by releasing the adsorbed gases. This cycle ensures a continuous production of oxygen enriched air with purity levels typically ranging from 90% to 95%. PSA oxygen generators are known for their efficiency, reliability, and cost-effectiveness, making them suitable for industries such as healthcare, water treatment, and manufacturing.

By using PSA technology, these systems deliver a consistent and dependable oxygen supply, eliminating the need for external oxygen sources.

Advantages of BERG GaseTech’s PSA Oxygen Generators

BERG GaseTech’s PSA oxygen generators offer numerous benefits over traditional oxygen production methods. Our systems provide high purity oxygen, making them ideal for various industrial applications.

They are designed to be cost-effective, delivering lower operating costs compared to liquid oxygen systems. The advanced PSA technology ensures a reliable and continuous oxygen supply with minimal energy consumption.

Additionally, our PSA oxygen generators require minimal maintenance and boast robust construction, offering a long service life that often exceeds 10 years. The compact design makes them suitable for demanding industrial environments, ensuring consistent performance and high-quality oxygen supply.

Applications of PSA Oxygen Generators

BERG GaseTech’s PSA oxygen generators are highly versatile and cater to a wide range of industries, delivering reliable and high-purity oxygen for various critical applications. Here’s an in-depth look at how these systems are used across different sectors:

Medical

Our PSA oxygen generator provides on-site oxygen generation, ensuring a reliable supply of high-purity oxygen for patients in hospitals and medical facilities. This is crucial for respiratory therapy, anesthesia, and other medical applications, reducing dependency on cylinder deliveries and enhancing patient safety with a continuous oxygen supply.

Ecology Fish Farming

For fish farming, maintaining optimal oxygen levels is vital for the health and growth of aquatic organisms.

Our PSA system ensures a consistent supply of high-purity oxygen, promoting healthier fish populations and improving yield and product quality. This leads to more efficient and sustainable fish farming operations.

Biogas Plants

In biogas plants, PSA technology is essential for optimizing the production of biogas. High-purity oxygen is used to enhance the efficiency of anaerobic digestion processes, resulting in increased biogas yield and improved overall plant performance. This contributes to more sustainable and cost-effective energy production.

Metal Industry

In the metal industry, our system has a crucial role in processes such as steel making, nonferrous metal smelting, and cutting applications. High-purity oxygen is used to improve combustion efficiency, increase production rates, and enhance the quality of metal products. The reliable supply of oxygen ensures consistent and cost-effective operations.

Glass & Neon Factory

In glass and neon manufacturing, high-purity oxygen is essential for achieving high temperatures and clean combustion. Our PSA oxygen systems provide a stable and continuous oxygen supply, enhancing the quality and precision of glass and neon products. This results in higher production efficiency and reduced operational costs.

Processing

Our oxygen generator is widely used in various processing industries for applications such as oxidation reactions, chemical production, and food processing. High-purity oxygen improves the efficiency and safety of these processes, ensuring better product quality and compliance with industry standards.

How PSA Technology Works for Oxygen and Nitrogen Generators

PSA (Pressure Swing Adsorption) technology is an advanced method used in oxygen and nitrogen generators to separate these gases from atmospheric air.

The process involves two towers filled with carbon molecular sieves (CMS) and zeolite molecular sieves. When compressed air is introduced, the molecular sieve capture nitrogen, allowing oxygen to pass through and be collected at the generator outlet.

During the high-pressure phase, the sieves adsorb nitrogen, carbon dioxide, and water vapor, producing high-purity oxygen. The system alternates between two tanks: one tank absorbs while the other regenerates by reducing pressure, releasing the adsorbed gases back into the atmosphere.

This alternating cycle ensures continuous and stable production of high-purity oxygen or nitrogen.

Key elements of PSA technology include:

- Dual-tower System: Ensures continuous operation by alternating between adsorption and desorption phases.

- Carbon Molecular Sieves (CMS): Capture nitrogen molecules during the adsorption phase.

- Zeolite Molecular Sieves: Enhance the separation process for high-purity oxygen production.

- Pressure Swing Adsorption: The process relies on pressure changes to separate and produce gases efficiently.

- Energy Efficiency: Low energy consumption due to advanced technology and optimized operation cycles.

- Minimal Maintenance: Designed for long-term use with minimal maintenance requirements.

PSA oxygen and nitrogen generators from BERG GaseTech are designed for reliability and efficiency, making them suitable for various industrial applications where a consistent and high-purity gas supply is critical.

Why Choose BERG GaseTech’s PSA Oxygen Generators?

- High Purity Oxygen: Our systems produce oxygen with purity levels up to 95%, ideal for various industrial and medical applications.

- Cost-Effective: Lower operating costs compared to liquid oxygen systems.

- Reliable Supply: Continuous and dependable oxygen production ensures operational efficiency.

- Energy Efficient: Advanced PSA technology ensures low energy consumption.

- Minimal Maintenance: Designed for long service life with minimal maintenance requirements.

- Robust Construction: Compact and durable design suitable for demanding industrial environments.

Ready to implement a reliable on-site oxygen generation solution? Contact BERG GaseTech’s sales team today to discuss your OXYBERG® PSA oxygen system needs. We look forward to providing a solution that enhances your efficiency and operational performance.

FAQ – Frequently Asked Questions

A PSA oxygen plant separates oxygen from air using molecular sieve and pressure changes, producing oxygen on-site at high purity levels.

A liquid oxygen plant, on the other hand, involves cryogenic distillation to produce liquid oxygen, which is then stored and transported.

Liquid oxygen plants can achieve higher purity levels but involve more complex infrastructure and higher operational costs.

PSA oxygen generators may have higher initial setup costs compared to traditional methods. They also require regular maintenance to ensure optimal performance and might not achieve the same purity levels as liquid oxygen plants for certain high-purity requirements.

However, PSA systems offer continuous on-site oxygen production, lower operational costs, and greater efficiency for many industrial applications.