Optimizing Electronics Manufacturing with Advanced Nitrogen Generators

In the electronics industry, precision and reliability are paramount, especially during processes like selective soldering. BERG GaseTech’s PSA nitrogen generators provide a continuous and high-purity nitrogen supply, creating an inert atmosphere essential for soldering with nitrogen. This not only enhances solder joint quality but also reduces oxidation, ensuring superior product performance.

Key Advantages of Nitrogen Generators in Electronics Manufacturing

Continuous Nitrogen Supply

Our nitrogen generators deliver a steady, on-demand nitrogen source, ensuring a constant protective atmosphere during selective soldering and other electronic manufacturing processes. This eliminates the dependency on external nitrogen supplies, reducing operational disruptions.

Customizable Purity and Output

BERG GaseTech’s nitrogen generators allow precise control over nitrogen purity and flow rates, catering to specific requirements of various electronic manufacturing processes, including nitrogen for welding and soldering with nitrogen.

Eco-Friendly and Sustainable

On-site nitrogen generation system reduces the environmental impact by minimizing transportation emissions and waste associated with cylinder deliveries, supporting sustainable manufacturing practices.

Benefits of Our Gas Generators for the Electronic Industry and Soldering

- High Purity Nitrogen for Precise Soldering: Our PSA nitrogen generators provide consistent, high-purity nitrogen (up to 99.999%), which is essential for critical electronic manufacturing processes like selective soldering, wave soldering, and reflow soldering. The clean nitrogen atmosphere minimizes oxidation, resulting in cleaner joints and better conductivity.

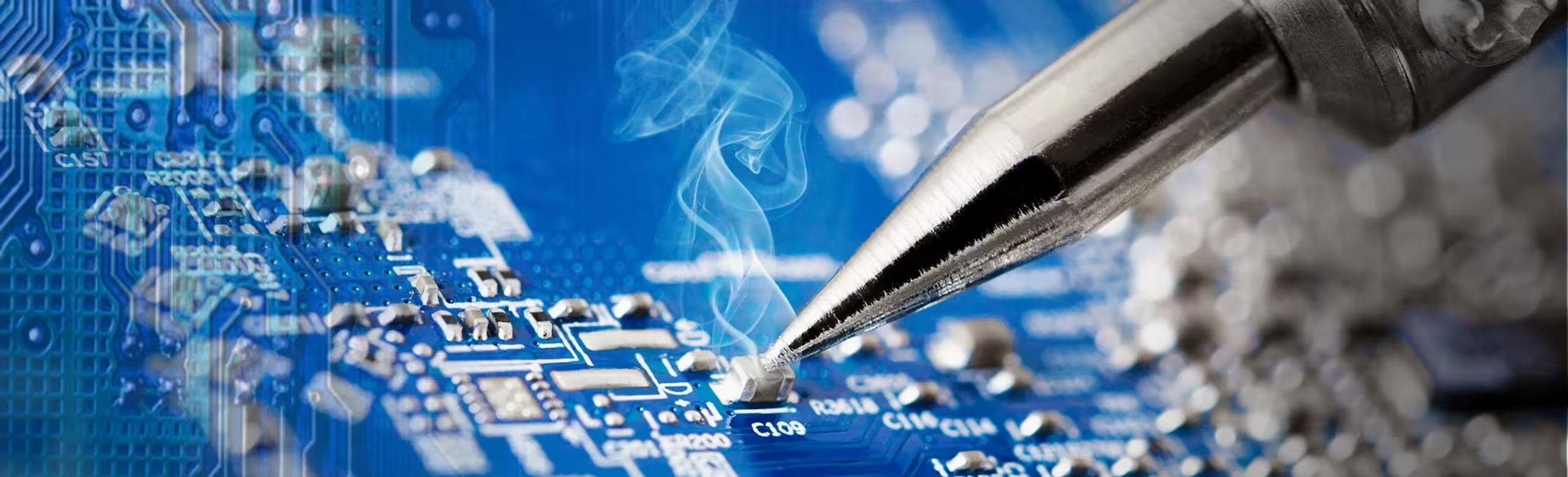

- Improved Solder Quality and Reduced Defects: Using nitrogen for soldering helps reduce solder balling, bridging, and void formation. This leads to stronger, more reliable solder joints—especially important for high-density circuit boards and delicate components in the electronics industry.

- On-Demand, On-Site Nitrogen Supply: Eliminate the dependency on liquid nitrogen deliveries or cylinder refills. Our gas generators deliver nitrogen for welding and soldering on demand, ensuring uninterrupted production and enhanced flexibility.

- Enhanced Process Control: Precise control of nitrogen flow and purity enables manufacturers to fine-tune the soldering environment. This is critical for advanced soldering processes like soldering with nitrogen, where small variations can impact overall product quality.

- Compact, Scalable Design: Our systems are compact and easy to integrate into existing production lines. Whether for small-scale prototyping or high-volume PCB assembly, BERG gas generators scale with your business.

Applications of Nitrogen Generators in Electronics Manufacturing

- Selective Soldering: Ensures an oxygen-free environment, improving solder joint quality and reducing defects.

- Wave Soldering: Maintains consistent nitrogen atmosphere, enhancing soldering efficiency.

- Reflow Soldering: Provides controlled nitrogen environments, crucial for high-quality soldering outcomes.

- PCB Assembly: Prevents oxidation during assembly, ensuring long-term reliability of electronic components.

Innovative PSA Technology

Our Pressure Swing Adsorption (PSA) technology efficiently separates nitrogen from compressed air, delivering high-purity nitrogen essential for electronic manufacturing. This technology ensures consistent nitrogen quality, vital for processes like soldering with nitrogen.

Enhance Your Electronics Manufacturing with BERG GaseTech

Integrating BERG GaseTech’s nitrogen generators into your electronic manufacturing processes ensures improved product quality, operational efficiency, and cost savings. Experience the benefits of reliable on-site nitrogen generation tailored to your specific needs.

Get Started with PSA Nitrogen Generators

Contact us today to learn more about how our nitrogen generators can optimize your electronics manufacturing processes.