Nitrogen Maker & Generation Systems – Reliable PSA Nitrogen Plants

At Berg GaseTech, we specialize in state-of-the-art Nitrogen Generation Systems utilizing Pressure Swing Adsorption (PSA) technology. Our advanced solutions enable businesses to produce high-purity nitrogen on-site, eliminating the need for expensive bottled or liquid nitrogen deliveries.

Whether you require a nitrogen maker for small-scale applications or a comprehensive nitrogen gas generation system for industrial use, we offer customized solutions designed to enhance efficiency, reduce operational costs, and ensure a consistent nitrogen supply.

PSA Nitrogen Package and High-Efficiency Nitrogen Plant

At BERG Gasetech, we specialize in state-of-the-art nitrogen plants using Pressure Swing Adsorption (PSA) technology to deliver high-purity nitrogen with exceptional efficiency and reliability. Our advanced NITROBERG® generators enable on-site nitrogen production, eliminating the need for costly and complex nitrogen cylinder transportation. Designed for flexibility and scalability, our nitrogen generation solutions cater to various industries, including food packaging, electronics, and industrial manufacturing, ensuring a continuous and independent nitrogen supply tailored to your operational needs.

Why Choose Our Nitrogen Generation Systems?

On-Demand Nitrogen Supply – Produce high-purity nitrogen whenever required..

Cost-Efficient & Sustainable – Achieve significant savings compared to traditional nitrogen cylinders.

Customizable Nitrogen Plants – Tailored to meet specific purity and flow rate requirements.

Low Maintenance & Easy Installation – Designed for hassle-free setup with minimal servicing needs.

Energy-Efficient PSA Technology – Engineered to optimize power consumption.

How Our PSA Nitrogen Maker Works

Our PSA nitrogen gas generation system separates nitrogen from compressed air through an advanced adsorption process.d air through an advanced adsorption process.

Step-by-Step Process:

- Air Compression & Filtration – Ambient air is compressed and filtered to remove moisture and contaminants

- Adsorption Phase – Oxygen molecules are captured by carbon molecular sieves (CMS), allowing nitrogen to pass through.

- Nitrogen Purification – The extracted nitrogen is further purified to achieve the desired purity level.

- Continuous Operation – A dual-tower design ensures an uninterrupted supply by alternating between adsorption and regeneration phases.

This process ensures a reliable and efficient production of high-purity nitrogen, suitable for various industrial applications.

Industries That Rely on Our Nitrogen Plants

Our Nitrogen Generation Systems provide a reliable and cost-effective solution for industries requiring high-purity nitrogen. By ensuring a consistent and on-demand nitrogen supply, our nitrogen makers enhance operational efficiency, reduce dependency on external suppliers, and improve product quality across multiple sectors:

Food & Beverage

Used in packaging and preservation to extend shelf life, prevent oxidation, and maintain product freshness.

Pharmaceuticals

Essential for nitrogen blanketing, ensuring the stability and purity of sensitive products by preventing moisture and contamination.

Electronics & Semiconductor

Provides an inert atmosphere for soldering, preventing oxidation and enhancing the reliability of electronic components.

Chemical & Petrochemical

Prevents oxidation and hazardous reactions by creating an oxygen-free environment in storage tanks, pipelines, and reactors.

Metal Processing

Used in laser cutting, heat treatment, and metal fabrication to prevent oxidation, improve precision, and enhance material quality.

Our nitrogen makers offer a sustainable, efficient, and scalable solution for industries requiring a continuous and high-purity nitrogen supply.

Customized Nitrogen Plants for Your Needs

We design nitrogen makers and nitrogen plants with:

- Purity Levels: 95% to 99.999%

- Flow Rate & Capacity Adjustments

- Seamless Integration with Existing Systems

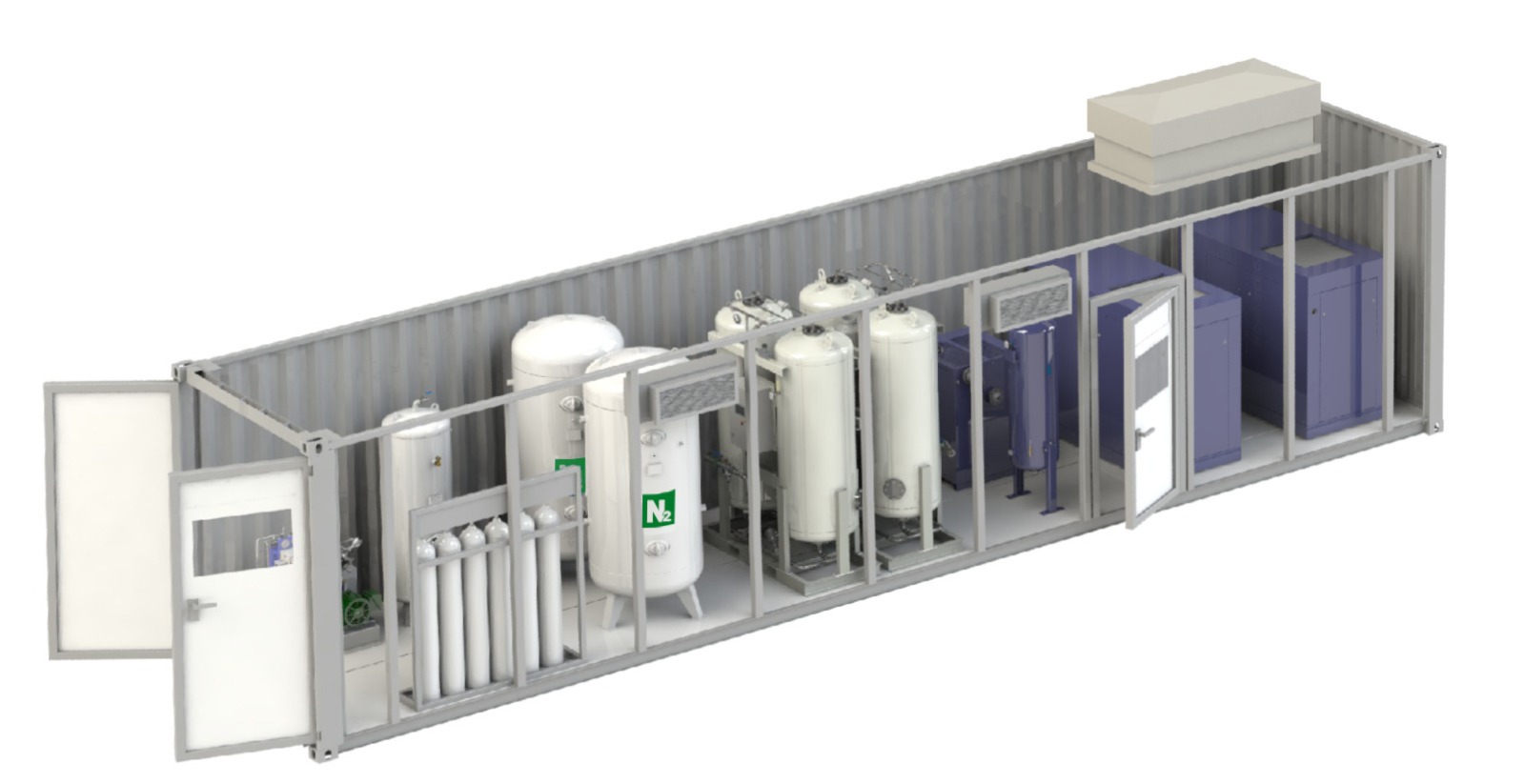

NITROGEN PLANT

Compressed Air Specification

- Temperature range: +5 to +40ºC

- Air quality: ISO 8573.1, Class 1.4.1

- Operation pressure: 10 bar

The Complete Nitrogen Plant, Skid Mounted

- Compressed Air Station

- Air treatment to ISO 8573-1 Class 1.2.1

- Compressed Air Buffer Tank

- PSA Nitrogen Generator, NITROBERG®

- Product Nitrogen Tank

- Boosting Station / Cylinder Filling Station

Ambient Conditions

- Temperature range: +5ºC to +40ºC

- Electrical connection: 110-230 V/60-50 Hz

- Noise level: from 55 to max. 78 dB(A)

- Accordance with DIN ISO 13485:2003 & European Directive 68/2014/EU

Why Choose BERG Gasetech for PSA Nitrogen Generators?

Partnering with BERG Gasetech means working with a trusted leader in nitrogen generation technology. Our nitrogen generators are designed for high efficiency, reliability, and cost-effectiveness, catering to a wide range of industries. Here’s why businesses worldwide rely on us:

Expertise & Innovation

With extensive experience in gas generation, we offer state-of-the-art PSA nitrogen generators that ensure a stable, high-purity nitrogen supply while optimizing energy efficiency and sustainability.

Global Reach with Local Support

Our worldwide presence guarantees timely assistance, including installation, training, and maintenance, ensuring smooth operation for your nitrogen production system—wherever your facility is located.

Customized Nitrogen Solutions

Every nitrogen generator is tailored to meet the specific needs of your industry, maximizing efficiency and reducing operational costs without compromising nitrogen purity.

Get Your PSA Nitrogen Maker Today!

By choosing Berg Gasetech’s nitrogen generation systems, you invest in a solution that offers reliability, efficiency, and adaptability to your specific industrial needs, Reduce costs and ensure a reliable nitrogen gas generation system.

📞 Call us now or 📩 Send an inquiry for a custom nitrogen solution!