Introduction to Oxygen Generator PSA Systems

PSA (Pressure Swing Adsorption) systems are vital for industries that want consistent oxygen delivery. These systems produce oxygen while wanted, so there may be no reliance on traditional oxygen cylinders or bulk deliveries. With their capability to provide excessive-purity oxygen cost-efficiently, PSA oxygen generators are extensively utilized in healthcare, aquaculture, wastewater remedy, and production. Their advanced era assists industries in meeting operational and environmental dreams, even ensuring uninterrupted oxygen availability.

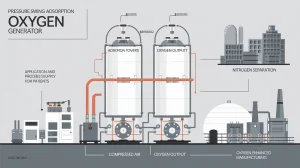

How Does an Oxygen Generator PSA System Work?

Core Technology Behind PSA Systems

The coronary heart of a PSA device is on the PSA tool’s coronary heart. Compressed air, which incorporates about 78% nitrogen and 21% oxygen, is processed using molecular sieves like zeolites. These sieves selectively adsorb nitrogen, permitting oxygen to pass through as a purified fuel.

Step by Step Process

- Air Compression and Pre-Treatment: Ambient air is compressed and surpassed via filters to cast off impurities, including moisture, dirt, and oil particles.

- Adsorption Cycle: The purified compressed air enters adsorption vessels packed with zeolite, which traps nitrogen molecules under excessive pressure.

- Desorption and Regeneration: During the desorption phase, the nitrogen is launched at a reduced strain degree, regenerating the zeolite for reuse.

- Oxygen Collection: The ultimate oxygen is saved in a buffer tank or used directly for applications.

The alternating adsorption and desorption cycles ensure non-stop transport of excessive-purity oxygen, making PSA systems green.

Applications of Oxygen Generator PSA Systems

1. Healthcare and Medical Use

Healthcare centres want steady oxygen for affected person care, mainly in intensive care units (ICUs), operating rooms, and emergency departments. PSA oxygen turbines offer this consistent supply at some stage in busy instances, pandemics, or herbal screw-ups.

Organization: The World Health Organization (WHO) recommends using PSA oxygen systems to help remedy oxygen shortages in developing areas.

2. Aquaculture and Fish Farming

In aquaculture, retaining high oxygen levels in the water is important for fish growth and health. PSA oxygen mills are a great way to add oxygen to the water, enhancing fish survival rates and boosting productivity.

- The Food and Agriculture Organization (FAO) acknowledges the PSA era’s sizable role in advancing sustainable practices in aquaculture.

3. Wastewater Treatment

Oxygen is an important issue in organic wastewater treatment processes. PSA structures ensure a regular and cost-effective oxygen supply for aeration, assisting in improving treatment performance and decreasing ordinary strength prices.

- Notable Organization: The Environmental Protection Agency (EPA) highlights oxygen optimization as crucial in robust wastewater control.

4. Industrial Applications

PSA oxygen systems are widely used in the steel, glass, and chemical processing industries. They permit green combustion, oxidation reactions, and vital methods while reducing operational prices.

- Notable Organization: The International Energy Agency (IEA) promotes electricity-efficient eras like PSA systems to assist commercial enterprise sustainability desires.

Benefits of PSA Oxygen Generators

1. Cost Efficiency

PSA structures make oxygen generators suppliers, eliminating the need to pay for cylinder deliveries and storage. This helps reduce daily operational costs considerably.

2. High Oxygen Purity

PSA oxygen mills supply oxygen with purity degrees from 90% to ninety-9 %, making them suitable for many commercial and clinical packages.

3. Energy Efficiency

Modern PSA structures are designed to optimize electricity consumption, making them an inexperienced opportunity for preferred oxygen supply techniques.

4. Scalability

PSA structures can be custom-designed for small-scale operations or adequate commercial vegetation to fulfil various oxygen demands.

5. Reliability

PSA systems offer non-stop and reliable oxygen delivery, eliminating dependency on outdoor logistics or shipping chain disruptions.

Environmental Impact of PSA Systems

PSA oxygen turbines aren’t the maximum green if they’re environmentally sustainable. Here’s how:

- Reduced Transportation Emissions: On-site, online oxygen technology eliminates the need to move cylinders, slashing related carbon emissions.

- Minimal Waste: Unlike cylinder-primarily based structures, PSA systems reduce reliance on disposable bins, decreasing waste minimization.

- Energy Optimization: The strength-green layout of PSA mills aligns with global green strength desires.

With the developing awareness of sustainability, PSA systems are becoming the preferred choice for industries aiming to reduce their environmental footprint.

Key Factors to Consider When Choosing a PSA Oxygen Generator

1. Capacity

Evaluate your oxygen name to select a generator with the proper manufacturing functionality. Over- or under-sizing the device can impact efficiency and fees.

2. Oxygen Purity

Different programs have various oxygen purity necessities. Ensure the PSA system can supply the required purity for your specific use case.

3. Maintenance

Choose a PSA generator with minimal maintenance necessities and readily available spare additives to ensure long-term reliability.

4. Energy Consumption

Opt for power-green systems to lower operational expenses and help sustainability projects.

5. Technical Support

Partner with a dependable supplier that offers vital technical steerage and after-income services. This ensures outstanding performance and quick decisions on any issues.

The Future of PSA Oxygen Generators

As industries continue to prioritize performance and sustainability, the adoption of PSA oxygen generators is anticipated to grow. Advancements in the substance era and automation are using enhancements in the PSA era, improving standard overall performance and decreasing charges. These systems also address global demanding situations, including healthcare getting the right of access and environmental sustainability.

FAQs on Oxygen Generator PSA Systems

Q.1 What is the predominant benefit of a PSA oxygen generator?

PSA oxygen generators provide a dependable and cost-effective online web page solution, eliminating the need for oxygen cylinders and delivery chain dependencies.

Q.2 How long does a PSA oxygen generator last?

With proper renovation, PSA oxygen mills typically have a lifespan of 10–15 years or more.

Q.Three Are PSA systems suitable for small corporations?

Yes, PSA structures are scalable and may be tailored to meet the wishes of small organizations similar to extensive business operations.

Q.Four What purity tiers can PSA oxygen turbines attain?

PSA structures commonly produce oxygen with purity tiers between 90% and 99%, depending on the utility.

Q.Five Do PSA oxygen turbines require fashionable upkeep?

No, PSA structures are designed for low-protection operation, requiring only periodic servicing to ensure the maximum beneficial ordinary overall performance.