Oxygen Generators for Biogas Plants

Oxygen generators for biogas play a key role in enhancing the efficiency of anaerobic digestion and other processes in biogas plants. By providing a reliable and cost-effective oxygen supply, PSA oxygen generators help improve biogas yields, reduce operational costs, and make production more sustainable.

This technology is both efficient and cost-effective, making it a preferred choice for industries requiring a reliable oxygen supply.

Harnessing Energy from Waste: Understanding Biogas Plants

Biogas is a renewable source of energy generated from the decomposition of organic waste in the absence of oxygen, through a process called anaerobic digestion. This natural breakdown produces biogas, mainly composed of methane and carbon dioxide, which can be used for cooking, heating, electricity generation, or upgraded to fuel vehicles.

A key component in many biogas systems is the need for controlled oxygen supply—especially during purification processes or when integrated with other renewable systems like composting or wastewater treatment. In such cases, an oxygen generator can play a vital role by supplying pure oxygen for specific reactions or supporting microbial activity in aerobic processes.

Among the companies advancing this technology, EnviTec Biogas AG (Germany) is a global leader in integrated biogas solutions, offering complete plant construction and gas upgrading.

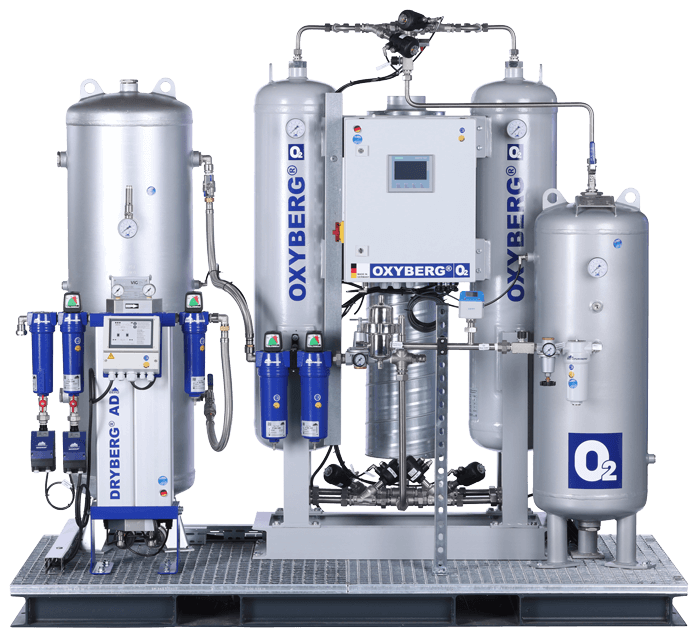

Key Features of BERG PSA Oxygen Generators for Biogas Plants

Low Operating Costs:

Low power demand, affordability, and reliability make PSA oxygen generators ideal for biogas oxygen production.

Compact Design:

These generators are compact and can easily be installed into the biogas plants irrespective of their size.

Automated Operation:

Some PSA oxygen generators are associated with intelligent control systems where oxygen flow can be regulated without needing to open the control panel frequently.

High Purity Levels:

PSA generators can supply up to 95% pure oxygen, which meets the quality standards expected of biogas plants.

Maximizing Biogas Yield with Oxygen Generators for Biogas

Biogas is mainly generated from anaerobic digestion, where bacteria decompose organic materials into methane and other related gases. Introducing oxygen into this process might appear a bit unreasonable since AD is generally carried out under no oxygen conditions. However, controlled oxygen injection improves specific phases, including desulphurization, which significantly increases the quality of the resultant gas.

Oxygen helps to decrease the content of hydrogen sulphide (H₂S). Content of hydrogen sulphide (H₂S) conservationists have pointed out that biogas contains another dangerous by-product, hydrogen sulphide (H₂S), which can corrode engines, turbines, and pipelines. Through this concept of utilising the oxygen generators for biogas plants, the H₂S content is conveniently removed, enhancing biogas’ efficacy and quality.

How PSA Oxygen Generators Benefit Biogas Plants ?

Implementing oxygen generators for biogas processes offers several key benefits that improve the overall efficiency and output of the plant:

1. Enhanced Biogas Quality with Oxygen for Biogas

The enhancement of oxygen increases the efficiency of biogas and the degradation of undesirable compounds, hence purer biogas. Biogas plants can make the hope of having a high-quality final product result possible by eliminating unpleasant contaminants such as hydrogen sulphide.

2. Cost Savings

Usually, methods like allocating external cylinders of oxygen add a lot of expenses and inconvenience to the biogas plants. The PSA oxygen gas generators mean plants can produce their oxygen locally and do not have to buy the cylinders, transport them, or store them. This can lead to a vast number of savings.

3. Continuous Oxygen Supply

Oxygen supply is another necessity that biogas plants have to keep steady. PSA technology effectively sustains a constant flow of oxygen and guarantees that the plant receives enough of it to meet the requirements of the consumers. This stable oxygen supply aids in the efficiency and continuity of work. It is one of the numerous features the two vehicles have in common and is instrumental in enhancing a stable, efficient, and continuous operation.

4. Reduced Maintenance and Downtime

Cuts of H₂S result from using oxygen generators for biogas plants that protect equipment, pipelines, and the storage tank against corrosion. This increases the useful life span of some of these components, making it possible to have low levels of maintenance costs and, at the same time, reduce downtimes.

5. Environmental Impact

PSA oxygen generators also significantly decrease the dependence on other external sources of oxygen for emissions reduction in biogas plants. Bearing this PSA technology, biogas plants powered by BERG GaseTech GmbH can run more environmentally friendly, enhancing their environmental conservation efforts.

Technical Specifications

- Oxygen Purity: Our oxygen making machines are capable of producing oxygen with purity levels up to 95%, suitable for most industrial and medical applications.

- Flow Rates: The flow rates of our generators range from small units designed for specific applications to large systems capable of producing thousands of cubic meters of oxygen per hour.

- Pressure Levels: Our industrial oxygen generator can deliver oxygen at various pressure levels from 1-150bar, tailored to meet the needs of different industrial processes.

- Energy Efficiency: Designed with energy efficiency in mind, our generators utilize advanced control systems to optimize power consumption, ensuring cost-effective operation.

For more information on how our Oxygen Plants can benefit your operations, contact us today and let us help you achieve optimal oxygen generation for your biogas plant.

What our Gas Generators do for Biogas Plants?

1. Anaerobic Digestion

Enhanced Microbial Activity: Anaerobic digestion is a biological process where microorganisms break down organic matter in the absence of oxygen, producing biogas. Introducing oxygen into the digestion process using PSA oxygen generators can enhance microbial activity, leading to more efficient degradation of organic materials and increased biogas production.

Optimized Biogas Composition: The controlled addition of oxygen with PSA generators allows for the adjustment of the biogas composition. This optimization can result in a higher methane content in the produced biogas, improving its energy value.

2. Odor Control through Oxygen Generators for Biogas

Biological Odor Treatment: Biogas plants often produce unpleasant odors due to the decomposition of organic materials. PSA oxygen generators can be used to supply oxygen to biological treatment systems that help control and mitigate odors generated during the anaerobic digestion process.

3. Wastewater Treatment

Aeration Tanks: In wastewater treatment processes associated with biogas plants, aeration tanks are used to provide oxygen to microorganisms that facilitate the breakdown of pollutants. PSA oxygen generators contribute to the aeration process, supporting the effective treatment of wastewater.

Nutrient Removal: The controlled addition of oxygen through PSA generators aids in nutrient removal processes, such as denitrification and phosphorus removal, improving the overall efficiency of wastewater treatment in biogas plants.

4. Landfill Gas Utilization

Methane Enhancement: Landfill gas is generated as a byproduct of organic waste decomposition in landfills. PSA oxygen generators can be employed to introduce oxygen into the landfill, enhancing methane production. This, in turn, can improve the feasibility and efficiency of landfill gas utilization projects.

5. Biogas Upgrading

Oxygen Removal: Biogas produced from anaerobic digestion often contains impurities, including oxygen. PSA oxygen generators can be used in the upgrading process to remove oxygen from biogas, resulting in a purified methane-rich gas suitable for injection into natural gas pipelines or use as a clean fuel.

6. Combined Heat and Power (CHP) Systems

Optimized Combustion: In CHP systems that utilize biogas for power generation, PSA oxygen generators can contribute to optimized combustion conditions. This ensures efficient energy conversion and maximizes the electricity and heat output from the biogas.

7. Biological Desulfurization

Sulfur Removal: Biogas produced from certain feedstocks may contain sulfur compounds that need to be removed for environmental and equipment protection reasons. Oxygen addition through PSA generators can enhance biological desulfurization processes, leading to reduced sulfur content in the biogas.

FAQs

1. What is a PSA oxygen gas generator?

PSA oxygen gas generator is a pressure swing adsorption oxygen generation equipment that utilises high-purity air to produce oxygen suitable for various operations like biogas production.

2. Why do biogas plants need oxygen generators?

Adding oxygen decreases the amount of undesirable materials, such as hydrogen sulphide in biogas, which produces better and less corrosive gas meant for equipment maintenance.