Oxygen Generators for Wastewater Treatment: Eco-Friendly Solutions

Over the last decade and a half, industries around the globe have experienced an increase in the environmental requirement of dominating and treating wastewater as well as efficient water usage. Among the technologies that facilitate these interventions, oxygen generators have arisen as critical drivers of effective wastewater management and environmentally sound treatment. Oxygen generators stabilize the oxygen levels in treatment systems to support biological processes and support regulated oxygen levels to uphold regulatory compliance, as well as environmental objectives in the long term. In this article, the object, advantages, and outlook for the use of Oxygen generator in water treatment are investigated with reference to typical industrial and municipal applications.

The Role of Oxygen in Wastewater Treatment

In his elaboration on the wastewater treatment process, Biber says that oxygen plays a crucial role since it fosters aerobic biological activities that facilitate the degradation of organic constituents and cut the number of undesirable by-products. Mechanical aerators usually introduce oxygen in more conventional wastewater treatment systems to mix air with water. However, the application of these systems can be associated with high expenses, consuming a lot of energy, and needing more efficiency.

Using an oxygen generator, treatment facilities can deliver pure oxygen to aeration tanks or to lagoons where biosolids are spread, providing a perfect environment for bio-aerobic microbes. These microbes oxidize the stock in order to break down the odorous organic waste into an even smaller volume and boost biodegradation. In food processing, petrochemical, and pharmaceutical industries involved in the handling of high-strength wastewater, oxygen generators present an attractive solution that enhances the treatment process while at the same time minimizing environmental impacts resulting from wastewater treatment processes.

How Oxygen Generators Work in Water Treatment

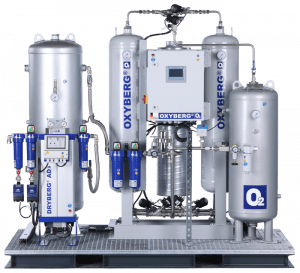

Anaubody oxygen generator uses technologies like Pressure Swing Adsorption (PSA) or Vacuum Swing Adsorption(VSA) to suck in oxygen from the atmosphere to provide oxygen for the treatment of wastewater. These systems isolate oxygen from nitrogen and other gases within the air and deliver up to 95% of oxygen.

The high-purity oxygen produced is released directly into aeration tanks or other treatment works, allowing microbial communities to enhance the degradation of organic matter. They operate within these facilities, meaning that the stock of oxygen is constant as compared to liquid oxygen. Where the use of oxygen is high, there is always pressure on L liquid oxygen to be suppliers. This helps to maintain an unbroken treatment process, which in turn helps make operations more dependable, economical, and eco-friendly.

Advantages of Using Oxygen Generators in Wastewater Treatment

Integrating oxygen-generating systems into wastewater treatment plants has several benefits, right from economic by way of saving costs to ecological. Here are some of the primary benefits:

- Lower Operating Costs: On-site oxygen production is cheaper than liquid oxygen and mechanical aeration methods of oxygenation. The ability to produce oxygen on the spot also eliminates the need for frequent delivery, cutting the cost of Oxygen supply.

- Energy Savings: In traditional systems of aeration, high energy is used to introduce enough oxygen into the water. Industrial oxygen generator are more efficient in the kind of oxygen supply they offer, so they use less energy and have fewer operational costs.

- Enhanced Treatment Performance: It increases the biological rates of decay of organic materials and hence enhances the rate of waste treatment processes. Privacy The paper also shows that using high-purity oxygen can increase the intensity of microbial activity, which will help water treatment facilities treat increased volumes of wastewater within a shorter period.

- Eco-Friendly Approach: New facilities have the added benefit of no longer relying on large amounts of electricity or chemical treatments, which can often release dangerous chemicals into the water. This contributes to the overall change in the methodologies to improve the existing methods of waste, especially in wastewater treatment, to meet environmental concerns’ expectations in industrial productivity and low production of wastages.

Industrial Applications of Oxygen Generators in Water Treatment

Oxygen generators are utilized in numerous industries with varying wastewater problems, including the food and beverage, petrochemical, pharmaceutical, and municipal industries. Ideal oxygen concentrations differ with each section of wastewater treatment, and therefore, oxygen generators come in handy to suit the sectors’ requirements.

For example:

- Food and Beverage Processing: Further, industries where the generated wastewater is organic-laden, such as dairies or breweries, require oxygen-generating systems to ensure that the required aerobic conditions are met in the breakdown of the wastes. Odor problems are eliminated, while high-efficiency microbial activity is enhanced through high-purity oxygen.

- Petrochemical and Pharmaceutical Industries: Some of these sectors handle sensitive wastewaters that need to be dealt with with great care. Oxygen generators provide specific oxygen concentrations required for the effective degradation of contaminants without posing chemical danger and fulfilling rigorous environmental requirements.

- Municipal Wastewater Treatment: There is ever-rising pressure on cities and towns to address the issue of wastewater management sustainably, and oxygen generators supplement the existing biological treatment systems used in cities’ public facilities.

Meeting Environmental Standards with Oxygen Generators

Oxygen generators help facilities meet the environmental requirements set down by different authorities, such as the EPA and IWA. These organizations are now stressing water reuse in the treatment of wastewater and safe water management with less energy input and minimal effects on the environment..

Oxygen generators can be adopted to reduce the use of energy-dependent conventional methods of aeration, which in turn produce a lot of waste. However, oxygen generators have a more concentrated method that indicates the wastewater treatment requirements and is environmentally friendly. Moreover, oxygen transported to organizations generates mobile emissions and, therefore, can take organizations a long way toward fulfilling environmental measures that seek to control emissions of greenhouse gases.

Future Prospects of Oxygen Generators in Wastewater Treatment

This shows that as technologies in the wastewater treatment industry advance, oxygen generators should feature to a much greater extent. Improvements in PSA and VSA technology are increasing the efficiency and availability of oxygen generation while sustainability is in focus globally, further boosting the demand for oxygen generators. Wastewater facilities are under pressure to find new, efficient, and environmentally friendly ways of treating wastewater; hence, oxygen generators will be sought after.

New oxygen generators may provide even more precise control of oxygen delivery, and such facilities will be able to disintermediate treatment in real time. Concerns for sustainability and compliance with regulatory requirements will further boost the growth of oxygen generator uses in a wide range of sectors and secure its place as fundamental equipment for contemporary wastewater treatment.

FAQ Section

Q1: What role does oxygen play in wastewater treatment?

A: Oxygen must facilitate aerobic digestion in wastewater so that organic materials can be digested, odor eliminated, and hazardous contents minimized.

Q2: How does an oxygen generator improve wastewater treatment efficiency?

A: In this method, oxygen generators provide high-purity oxygen directly into the treatment tanks; this improves the microbial work, thereby increasing the conversion rate of the organic material and the rate of work, thereby increasing efficiency.

Q3: Are oxygen generators more eco-friendly than traditional aeration methods?

A: In fact, oxygen generators are energy efficient compared to conventional aeration systems. They reduce energy consumption for chemical treatments and carbon footprint as they produce oxygen internally.

Q4: What types of industries benefit most from oxygen generators in wastewater treatment?

A: Petroleum refining, food and beverage processing, petrochemicals, pharmaceuticals, and the municipal wastewater treatment industry are a few of the industries that have greatly accrued the benefits of economical and reliable oxygen delivery from generators.

Q5: Can oxygen generators help facilities meet environmental standards?

A: Absolutely. It is easier for such facilities to meet the environmental requirements recommended by associations such as the EPA and IWA to support the oxygen generation method for wastewater treatment, thus minimizing the impact on the ecology.