High-Efficiency PSA Nitrogen Generator

Manufacture in Germany, BERG nitrogen generators exemplify superior engineering and stringent quality control, meeting the highest standards for performance and reliability. Our generators can be customised to address these specific needs, delivering optimal performance and efficiency tailored to your operations.

Understanding PSA Nitrogen Gas Generators

BERG GaseTech’s PSA nitrogen generators utilize advanced Pressure Swing Adsorption (PSA) technology to efficiently separate nitrogen from ambient air, providing a cost-effective and reliable nitrogen supply for various industrial applications.

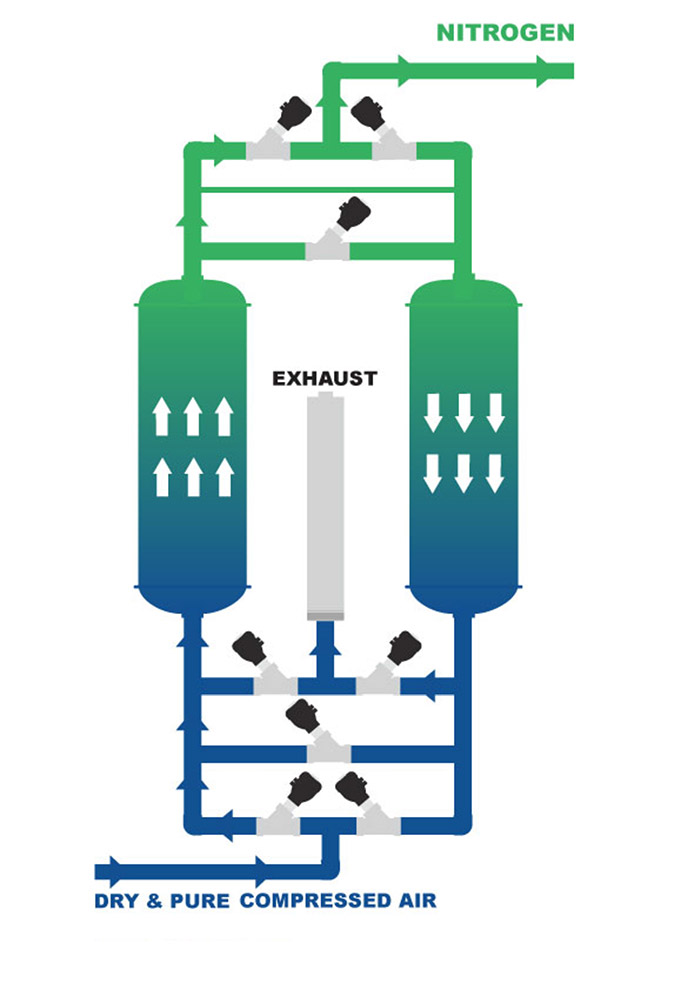

How does Nitrogen Generator work?

The PSA process takes advantage of the different adsorption properties of gases. Ambient air consists of approximately 78% nitrogen and 21% oxygen, along with trace gases. In a PSA nitrogen generator:

- Compression – Ambient air is compressed to the required pressure.

- Adsorption – The compressed air passes through adsorption towers filled with Carbon Molecular Sieves (CMS), which selectively adsorb oxygen, carbon dioxide, and moisture, allowing high-purity nitrogen to pass through.

- Desorption – Once the sieves become saturated with oxygen, the system releases the adsorbed gases by reducing pressure, regenerating the sieves for the next cycle.

- Continuous Operation – By alternating between two adsorption towers, the system ensures a steady and uninterrupted supply of nitrogen.

For a visual representation of this process, please refer to the diagram below:

PSA Nitrogen Generator Technology

Pressure Swing Adsorption (PSA) technology efficiently separates nitrogen from air using Carbon Molecular Sieves (CMS). Compressed air flows through two alternating adsorption towers, where oxygen, carbon dioxide, and moisture are adsorbed, allowing high-purity nitrogen to be collected. This cycle ensures a continuous nitrogen supply without relying on external sources.

PSA nitrogen generators offer a cost-effective, low-maintenance solution for various industrial applications, including food packaging, electronics manufacturing, metal fabrication, pharmaceuticals, and oil & gas industries.

Our PSA oxygen generators are designed in compliance with international standards, including:

- CE2912: Pressure Equipment Directive 2014/68/EU European Directive.

- ISO 13485: Quality management systems for medical devices.

Adherence to these standards ensures that our systems provide a consistent and dependable oxygen supply, suitable for critical applications across various industries.

Key Technical Specifications

- Nitrogen Purity: Adjustable up to 99.999%, catering to industry-specific needs.

- Flow Rate: Scalable models available, delivering nitrogen capacities to match various operational requirements.

- Operating Pressure: Standard systems function at 5-8bar, with customizable options available.

- Energy Efficiency: Optimized power consumption, ensuring cost-effective on-site nitrogen production.

- Compact and Modular Design: Facilitates seamless integration into existing industrial setups.

With their robust construction, minimal maintenance needs, and long service life exceeding 10 years, NITROBERG® PSA nitrogen generators provide an efficient and sustainable solution for industries requiring a steady supply of high-quality nitrogen.

Advantages of N2 PSA Systems

A PSA system for nitrogen offers several advantages over alternative nitrogen production methods:

- Cost Efficiency

By producing nitrogen on-site, businesses save significantly on recurring expenses like transportation, cylinder refills, and rental fees. - Continuous and Reliable Supply

Unlike gas cylinder supply, which requires frequent refills, an N2 PSA system ensures a constant and uninterrupted nitrogen supply. - Customizable Purity Levels

PSA N2 Generators allow users to select nitrogen purity levels ranging from 95% to 99.999%, depending on industry requirements. - Low Maintenance & Long Lifespan

A PSA gas generator requires minimal maintenance due to its simple yet robust design, ensuring a long operational lifespan with minimal downtime. - Eco-Friendly Solution

Since PSA systems eliminate the need for nitrogen transportation and storage, they contribute to reduced carbon emissions and promote a greener production process.

Technical Data of PSA Nitrogen Generator NITROBERG®

| Model | Nitrogen Purity Quality grade Residual O2(PPM) | 97% – – | 98% – – | 99% 2.0 10000 | 99.5% 2.5 5000 | 99.9% 3.0 1000 | 99.99% 4.0 100 | 99.995% 4.5 50 | 99.999% 5.0 10 |

| NITROBERG® 500 | N2, Nm3/h Comp.air, Nm3/h | 17.3 39.8 | 14.9 34.3 | 12.6 32.8 | 9.2 26.7 | 5.1 18.4 | 2.8 14.3 | 2.1 12.0 | 1.4 9.7 |

| NITROBERG® 600 | N2, Nm3/h Comp.air, Nm3/h | 25.9 59.6 | 22.6 52.0 | 18.1 47.1 | 13.4 38.9 | 7.2 25.9 | 3.9 19.9 | 2.9 16.5 | 2.1 14.5 |

| NITROBERG® 700 | N2, Nm3/h Comp.air, Nm3/h | 37.3 85.8 | 33.6 77.3 | 27.3 71.0 | 20.8 60.3 | 11.6 41.8 | 6.1 31.1 | 4.5 25.7 | 3.1 21.4 |

| NITROBERG® 800 | N2, Nm3/h Comp.air, Nm3/h | 49.6 114.1 | 44.6 102.6 | 36.3 94.4 | 27.6 80.0 | 15.4 55.4 | 8.2 41.8 | 5.9 33.6 | 4.1 28.3 |

| NITROBERG® 900 | N2, Nm3/h Comp.air, Nm3/h | 59.3 136.4 | 53.3 122.6 | 46.1 119.9 | 37.4 108.5 | 23.0 82.8 | 11.6 59.2 | 8.7 49.6 | 5.7 39.3 |

| NITROBERG® 1000 | N2, Nm3/h Comp.air, Nm3/h | 83.2 191.4 | 75.2 173.0 | 63.4 164.8 | 51.5 149.4 | 37.2 122.8 | 23.4 110.0 | 16.6 86.3 | 5.7 39.3 |

| NITROBERG® 1100 | N2, Nm3/h Comp.air, Nm3/h | 115.8 223.6 | 97.2 205.9 | 79.2 195.2 | 67.3 157.4 | 47.7 129.7 | 27.6 108.2 | 20.8 90.2 | 14.1 94.5 |

| NITROBERG® 1200 | N2, Nm3/h Comp.air, Nm3/h | 139.9 321.8 | 127.8 321.8 | 107.7 280.0 | 87.5 253.8 | 63.2 208.6 | 39.6 186.1 | 28.2 146.6 | 18.1 115.8 |

| NITROBERG® 1300 | N2, Nm3/h Comp.air, Nm3/h | 212.9 489.7 | 186.1 428.0 | 141.6 428.0 | 118.9 344.8 | 89.5 295.4 | 50.0 235.0 | 38.1 198.1 | 26.2 167.7 |

| NITROBERG® 1400 | N2, Nm3/h Comp.air, Nm3/h | 304.9 701.3 | 267.3 614.8 | 209.9 545.7 | 181.7 526.9 | 126.7 418.1 | 73.4 345.0 | 55.4 288.1 | 37.6 240.6 |

| NITROBERG® 1500 | N2, Nm3/h Comp.air, Nm3/h | 367.3 844.8 | 319.8 844.8 | 239.6 623.0 | 198.9 576.8 | 149.5 493.4 | 88.7 416.9 | 66.9 347.9 | 45.8 293.1 |

| NITROBERG® 1600 | N2, Nm3/h Comp.air, Nm3/h | 441.2 1,014.8 | 382.9 880.7 | 287.5 747.5 | 238.6 691.9 | 179.6 592.7 | 106.5 500.6 | 81.1 421.7 | 55.1 352.6 |

| NITROBERG® 1700 | N2, Nm3/h Comp.air, Nm3/h | 536.8 1,234.6 | 462.4 1,063.5 | 346.5 900.9 | 288.2 835.8 | 224.6 741.2 | 128.4 603.5 | 94.9 493.5 | 64.4 412.2 |

| NITROBERG® 1800 | N2, Nm3/h Comp.air, Nm3/h | 694.9 1,598.3 | 606.8 1,395.6 | 459.6 1,195.0 | 378.8 1,098.5 | 295.8 976.1 | 167.2 785.8 | 122.6 637.5 | 85.1 544.6 |

| NITROBERG® 1900 | N2, Nm3/h Comp.air, Nm3/h | 894.6 2,057.6 | 777.4 1,788.0 | 575.7 1,496.8 | 478.6 1,387.9 | 359.7 1,187.0 | 213.8 1,004.9 | 161.6 840.3 | 109.8 702.7 |

| NITROBERG® 2000 | N2, Nm3/h Comp.air, Nm3/h | 1,057.7 2,432.7 | 921.1 2,118.5 | 689.4 1,792.4 | 572.8 1,661.1 | 435.5 1,436.5 | 259.8 1,221.1 | 192.6 1,001.5 | 133.6 855.6 |

Competitive Pricing for BERG PSA N2 Generators

When evaluating the PSA nitrogen generator price, several factors influence the overall cost:

Capacity & Flow Rate: Higher flow rate models tend to be more expensive.

Purity Requirements: Systems that provide 99.99% – 99.999% nitrogen purity come at a premium.

Automation & Control Features: Advanced models with digital control panels and remote monitoring add to the cost.

Maintenance & Lifespan: Low-maintenance designs with durable components may have a higher initial price but lower long-term costs.

Applications of PSA Nitrogen Generators

BERG GaseTech’s PSA nitrogen generators are highly versatile, serving a wide range of industries by providing a reliable and high-purity nitrogen supply for various critical applications. Here’s an in-depth look at how these systems support different sectors:

Plastics & Packaging

Why Choose Our PSA Nitrogen Generators?

When selecting a PSA nitrogen gas generator, it’s crucial to consider quality, efficiency, and long-term value. we offer cutting-edge nitrogen generation systems with the following benefits:

German Engineering Excellence

Our PSA nitrogen generators are manufactured using high-quality components, ensuring precision, reliability, and long service life.

Wide Range of Models

We offer customized PSA nitrogen generators tailored to various industries, from small-scale operations to large manufacturing plants.

Cost-Effective Solutions

By choosing our PSA nitrogen system, you can significantly reduce operational costs, ensuring a high return on investment.

Industry-Leading Customer Support

Comprehensive installation assistance

Regular maintenance services

24/7 technical support for troubleshooting

Advanced Automation & Control

Our N2 PSA systems feature smart automation with remote monitoring capabilities, allowing real-time tracking of nitrogen purity, flow rate, and system efficiency.

By investing in BERG PSA nitrogen generators, businesses gain access to premium-quality nitrogen production solutions at the most competitive prices.

Contact our sales team today to discuss your ultra high purity PSA Nitrogen Generator needs. We look forward to providing a solution that elevates your industrial processes to new heights of performance and reliability.