Harnessing the Power of PSA Oxygen Generators in Glass and Neon Manufacturing

PSA oxygen generators are vital in the glass and neon manufacturing industries, offering a continuous, on-site source of high-purity oxygen. Their applications enhance efficiency, cost-effectiveness, and control over critical manufacturing processes, demonstrating their indispensable role.

By integrating advanced technologies like PSA oxygen generators, industries achieve better performance and sustainability, making them a cornerstone in modern manufacturing.

Key Benefits of Our Oxygen Generators

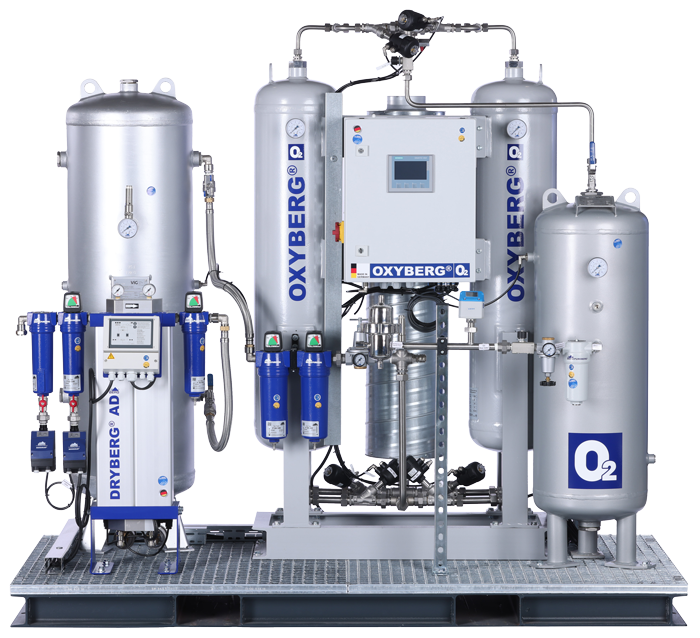

Proudly manufactured in Germany, our generators benefit from superior engineering and rigorous quality control, ensuring they meet the highest standards of performance and reliability.

Enhanced Production Efficiency

Our oxygen generators provide high-purity oxygen, crucial for the precision required in glass blowing and neon light production. Experience smoother operations and higher quality outputs with our state-of-the-art technology.

Cost Effective Solutions

Eliminate the dependency on external oxygen supplies. Our onsite oxygen generation system leads to substantial cost savings and enhanced operational efficiency, allowing you to allocate resources more effectively.

Continuous Oxygen Supply

Our generators are designed for unparalleled reliability, ensuring a continuous and uninterrupted supply of oxygen. This consistency is essential for maintaining optimal production processes in your factory.

Customizable Systems

We understand that each glass and neon manufacturing facility has unique needs. Our flexible solutions are tailored to meet specific flow and purity requirements, ensuring our systems integrate seamlessly into your production line.

Technical Specifications

- Oxygen Purity: Our generators produce oxygen with purity levels up to 95%, ensuring optimal conditions for glass blowing and neon light production. High-purity oxygen enhances the quality and precision of your manufacturing processes.

- Flow Rates: Our systems are versatile, ranging from small units for specialized applications to large systems capable of producing thousands of cubic meters of oxygen per hour. This flexibility caters to the diverse requirements of various glass and neon manufacturing facilities.

- Pressure Levels: Our generators can deliver oxygen at pressure levels ranging from 1 to 150 bar, tailored to meet the specific needs of different stages in your production process. Whether you need low pressure for delicate glass work or high pressure for intensive applications, our systems are designed to adapt.

- Energy Efficiency: Engineered with energy efficiency in mind, our generators feature advanced control systems that optimize power consumption. This provides a cost-effective solution, reducing your energy bills while maintaining peak performance in your glass and neon manufacturing operations.

What Oxygen Generators Do in Glass Manufacturing

Oxy-Fuel Combustion

In glass manufacturing, high-temperature processes such as melting and forming benefit from oxy-fuel combustion, using pure oxygen instead of air to achieve higher temperatures and efficiency. PSA oxygen generators provide a continuous source of high-purity oxygen, ensuring optimal furnace performance, faster melting times, and improved productivity. This enhances efficiency and reduces fuel consumption and emissions, contributing to a sustainable manufacturing process.

Glass Blowing

Precise control over flame temperature is crucial in artistic and specialty glass blowing. PSA oxygen generators ensure a consistent and controllable oxygen supply, maintaining the exact temperatures needed for various types of glass, allowing for intricate designs and flawless finishes. This reliability enhances the quality and precision of glass blowing, making them indispensable in both artistic and industrial production.

Glass Cutting and Welding

Oxygen is essential in cutting and welding processes within the glass industry. PSA oxygen generators offer an on-site, cost-effective solution, eliminating the need for oxygen cylinders and reducing associated costs and logistical challenges. By providing a continuous supply of high-purity oxygen, these generators ensure efficient and precise operations, critical for high-quality glass products.

Oxygen Enrichment for Annealing

Annealing, used to relieve internal stresses and improve the strength and durability of glass products, benefits from oxygen enrichment. PSA oxygen generators provide the necessary high-purity oxygen, enhancing the efficiency of this process and resulting in better quality, more durable glass products.

What Oxygen Generators Do in Neon Sign Manufacturing

Tube Bending and Sealing

Neon signs involve bending glass tubes and sealing them with noble gases like neon or argon. PSA oxygen generators supply oxygen for controlled combustion during tube bending and sealing, ensuring proper formation and sealing, crucial for neon sign longevity and performance.

Neon Gas Production

Producing neon gas involves purifying it from a mixture of gases. PSA oxygen generators provide the necessary oxygen for effective gas separation, ensuring high-quality neon gas essential for vibrant neon signs.

Oxy-Hydrogen Flame for Glass Coating

An oxy-hydrogen flame is used in some neon sign manufacturing processes for coating glass tubes. PSA oxygen generators ensure a continuous and reliable oxygen supply, maintaining the flame needed for uniform and high-quality coating, enhancing the durability and appearance of neon signs.

General Applications

Flame Polishing

Flame polishing smooths and finishes glass surfaces in both glass and neon manufacturing. PSA oxygen generators provide the necessary high-purity oxygen, ensuring efficient and effective polishing, contributing to high-quality glass products.

Cutting and Welding

Oxygen is used in various metal cutting and welding processes. PSA oxygen generators support these processes by providing a continuous high-purity oxygen supply, ensuring efficient and precise operations, essential for high-quality metal products. Their versatility and reliability make them valuable in facilities with multiple manufacturing processes, enhancing overall efficiency.

Enhanced Manufacturing Efficiency

PSA oxygen generators are essential in the glass and neon manufacturing industries, offering a continuous, on-site source of high-purity oxygen. Their applications range from supporting high-temperature processes in glass manufacturing to various techniques in neon sign production. The use of PSA oxygen generators leads to increased efficiency, cost-effectiveness, and greater control over critical manufacturing processes.

By integrating advanced technologies like PSA oxygen generators, manufacturers achieve better performance and sustainability. These generators enhance productivity and product quality, contributing to environmentally friendly practices by reducing reliance on external oxygen supplies and minimizing waste, driving innovation and efficiency in both industries.

Optimizing Oxygen Use in Glass Production

The glass industry benefits from PSA oxygen generators, particularly in oxygen glass production, where pure oxygen optimizes combustion processes. Using pure oxygen reduces fuel consumption, leading to cost savings and improved environmental outcomes. Traditional combustion air, containing nitrogen, dilutes oxygen concentration and lowers combustion efficiency.

Pure oxygen enhances the glass melting process, allowing for higher temperatures and more efficient melting. Increased oxygen concentration also reduces NOx emissions, meeting environmental regulations and enhancing sustainability. Dilute oxygen combustion, where oxygen mixes with less air, improves combustion efficiency, reducing fuel consumption and emissions.

PSA oxygen generators provide a continuous high-purity oxygen supply, essential for implementing these techniques, leading to better resource utilization and sustainability.

In glass manufacturing, oxy-fuel burners enhance energy efficiency and reduce emissions. Using industrial gases, particularly oxygen from a PSA oxygen generator, creates a more efficient oxy-fuel furnace, reducing natural gas usage and lowering overall fuel consumption.

The high-purity oxygen supply improves combustion, resulting in higher temperatures and better melting glass efficiency. Additionally, this process reduces particulate emissions from glass furnaces, contributing to cleaner and more sustainable production.

Get Started with BERG GaseTech GmbH

Choosing Berg-Gasetech for your glass melting needs means embracing advanced technologies in industrial gases and oxy-fuel combustion. Their PSA oxygen generators optimize combustion air, enhancing the combustion process while significantly reducing NOx emissions.

Our solutions are designed to improve efficiency and lower operational costs. With a strong commitment to sustainability and innovation, we provide the expertise and reliable technology necessary to meet stringent environmental standards and boost your manufacturing performance.

Our expertise ensures that your combustion process is optimized for maximum efficiency and sustainability in glass melting operations. Trust us for top-tier gas solutions tailored to reduce NOx emissions and elevate your operations.